Success Story: NN., Inc.

TURNING LOWER-VALUE SCRAP INTO HIGHER REVENUE WITH RUF BRIQUETTING SYSTEMS

CLIENT

NN, Inc. located in Wellington, Ohio, designs and manufactures high-precision metal and plastic components and assemblies for a variety of markets worldwide.

EXECUTIVE SUMMARY

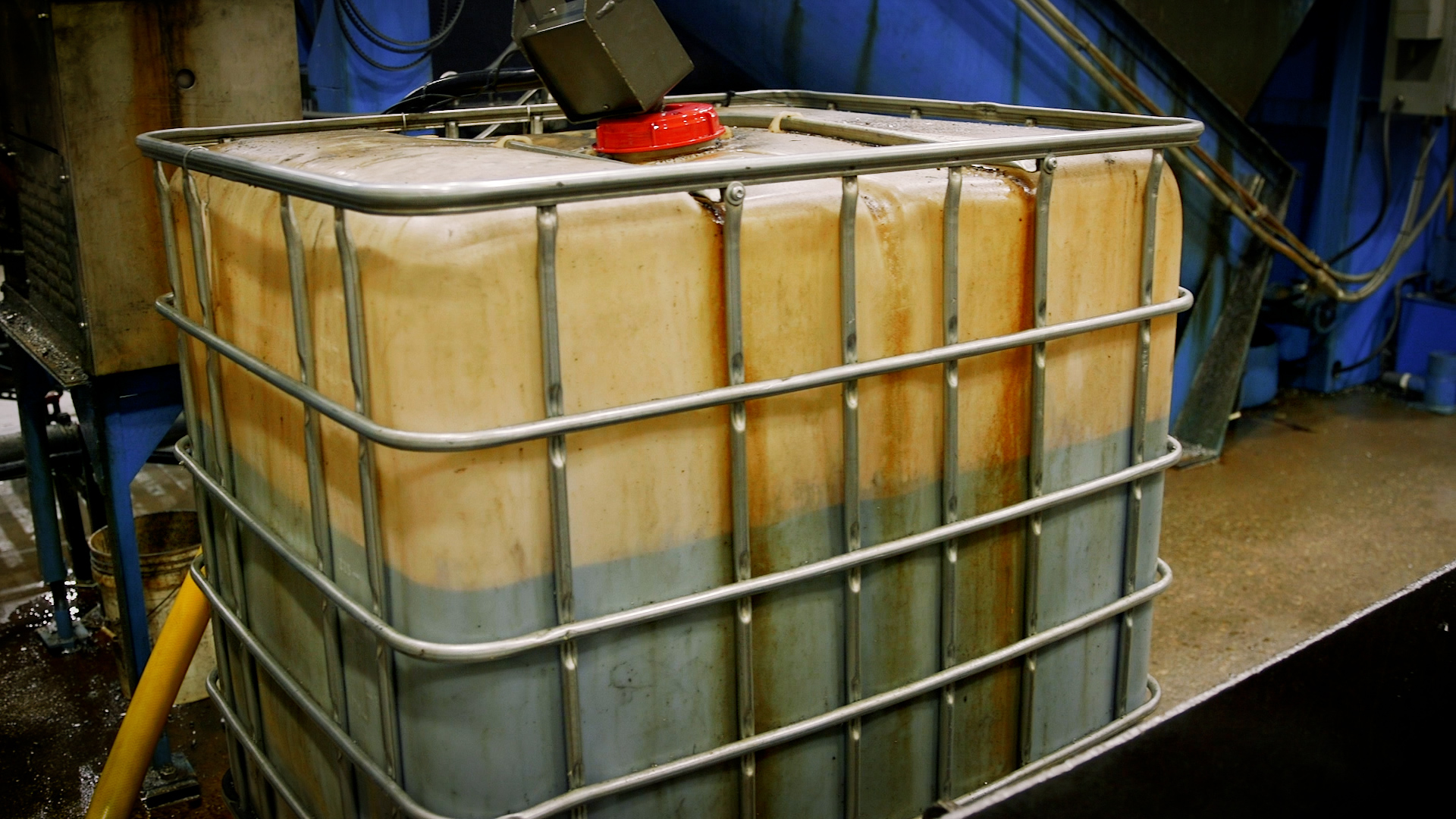

Every month, NN, Inc. invested in expensive cutting oil for their manufacturing processes. Their inefficient chip wringer left their chips oversaturated, forcing them to sell their metal for scrap, at a low cost. Frustrated that they couldn’t recover their oil or earn more for their chips, NN, Inc. asked RUF Briquetting Systems for help. RUF’s free briquette press test rapidly proved that RUF Briquetting Systems could eliminate excess fluid from the metal and extract up to 97% of their cutting fluid for reuse. NN, Inc. now recovers so much quality cutting fluid they are re-using it—saving them thousands of dollars a month. They are also re-selling briquettes at a higher price. “Briquettes offered us increased value for chips. Not only that, RUF is always available to assist us and help maximize profits for their customers,” said Mike McClure, Plant Manager.

CHALLENGE

Every month, NN, Inc. invested in expensive cutting oil for their manufacturing processes. Their inefficient chip wringer left their chips oversaturated, forcing them to sell metal for scrap, at a low cost. “We needed to maximize our value stream,” said Mike McClure, Plant Manager, NN, Inc.

SOLUTION

Frustrated that they couldn’t recover oil or earn more for their scrap, NN, Inc. sent RUF some of their material to process. RUF’s free briquette press test rapidly proved two things: 1. That RUF’s system could produce a denser, higher quality briquette quickly. And second, that RUF’s system could extract up to 97% of their cutting fluid for reuse. “The RUF team is extremely knowledgeable about their equipment and have demonstrated the capabilities to maximize our throughput,” said McClure.

results

NN, Inc. now saves up to $5,000 a month on cutting fluid—without the frustration or manual effort—using their RUF machine.

- Increased value for their briquettes

- Recycles and reuses their own cutting fluid

- Eliminates excess coolant on chips

- Increased value of raw material purchases