WHAT IS BRIQUETTING?

Briquetting systems take the process waste from metal and wood operations and turn it into something useful.

A RUF metal briquetting machine hydraulically presses the byproducts to create a dense, high quality product. No fillers, just high pressure.

What is the end product of the briquetting process?

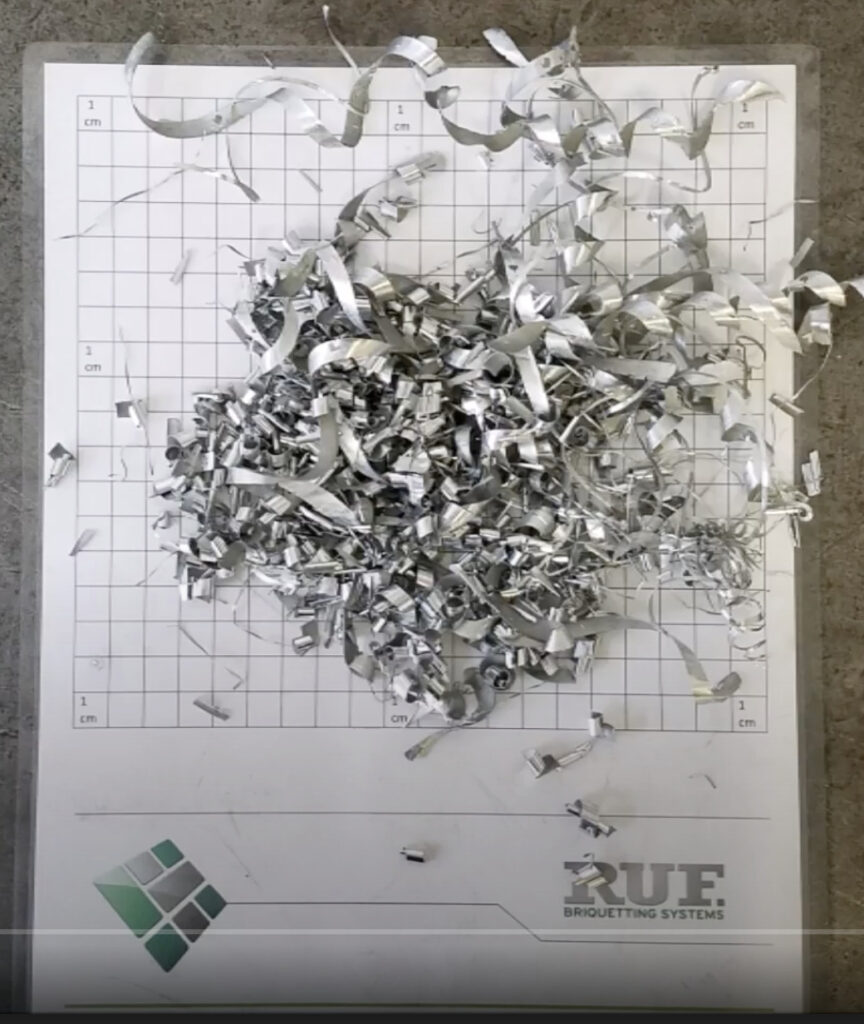

In the briquetting process, remnants like shavings, turning, chips—all that scrap piling up on the floor and equipment—are compressed into bricks or cylinders of valuable material.

Practically anything can be briquetted.

Our briquetters can handle it all—and then some. Briquetting scrap eliminates the costly hassle of waste and turns it into profits. When people ask, what is briquetting, they’re usually thinking about how it applies to their business. We’ve briquetted everything from wood scraps to diapers.

Types of briquettes: What materials can be turned into briquettes?

WOOD & BIOMASS

- Sawdust

- Wood Chips

- Cotton

- Hay

- Tobacco

- Cellulose

- Bark

- Straw

- Textile Dust

METAL

- Aluminium

- Brass

- Bronze

- Cast Iron

- Copper

- Magnesium

- Steel

- Titanium

- Zinc

- Sludge/Swarf

Briquetting solves the problem of process waste

Briquettes are far more valuable than shavings or chips. Briquetting is like turning waste into profits. In an easy-to-manage brick form, they can be sold or reused.

- Turn scrap into products that can be reused or recycled

- Create a new revenue stream by selling briquettes

- Reduce waste

- Eliminate costly hassles of waste disposal

What is briquetting going to do for a metal manufacturer?

On top of the benefits just listed, RUF briquetters can conquer the sludge problem. Our machines can squeeze value out of harmful sludge, so it’s easier to dispose of. And we can reclaim process fluids for recycling–or reuse in your own operations.

Find out more about metal briquetting >

What is briquetting going to do for a wood manufacturer?

Instead of wasting time sweeping and storing and transporting waste, you could be making money. You can sell wood briquettes on the home heating market as a carbon neutral fuel source.

Briquettes have been popular in Europe for years, and are taking off in North America as a flexible alternative to pellets, mainly because pellets are limited for use in pellet stoves, while briquettes can be used in any wood-burning device.

Find out more about wood briquetting >

Briquetting is increasingly popular

Briquetters are becoming the darlings of operations managers who need to cut costs and squeeze all the value they can out of existing resources. But not all briquetters are created equal.

Benefits of RUF Briquetters

At RUF, we stand behind everything we install—before, during, and after installation. Every high-quality machine comes with expert advice, technical assistance, and outstanding customer service.

- Easily integrated into existing production lines

- Small footprints

- Efficient hydraulics

- No fillers

- Low maintenance

- Automatic, 24/7 operation

How do you know if briquetting is right for your business?

The amount of material needed to make briquetting profitable depends on the price of the material and your company’s logistics. Briquetting requires less volume than most people think. And briquetting often pays for itself within 18 months, making it a smart move for those who want to squeeze all the value they can out of their raw materials.

The best way to see how briquetting can work in your business is to talk to a RUF briquetting expert, and get a sample of your material briquetted. It’s free, and can help you see what your ROI on briquetting would look like.

We know that finding ways to turn waste into revenue can be hard to come by. And we hope that this short article on “what is briquetting” was helpful to you. If we can answer other questions about metal or wood briquetting, please reach out to us.